Contribution

materials designfabrication

written/visual documentation

Collaborator

Humphrey YangKuanren Qian

Supervisor

Lining YaoConducted at Morphing Matter Lab, HCII, CMU

︎Accepted and presented at CHI '21!

︎Full paper

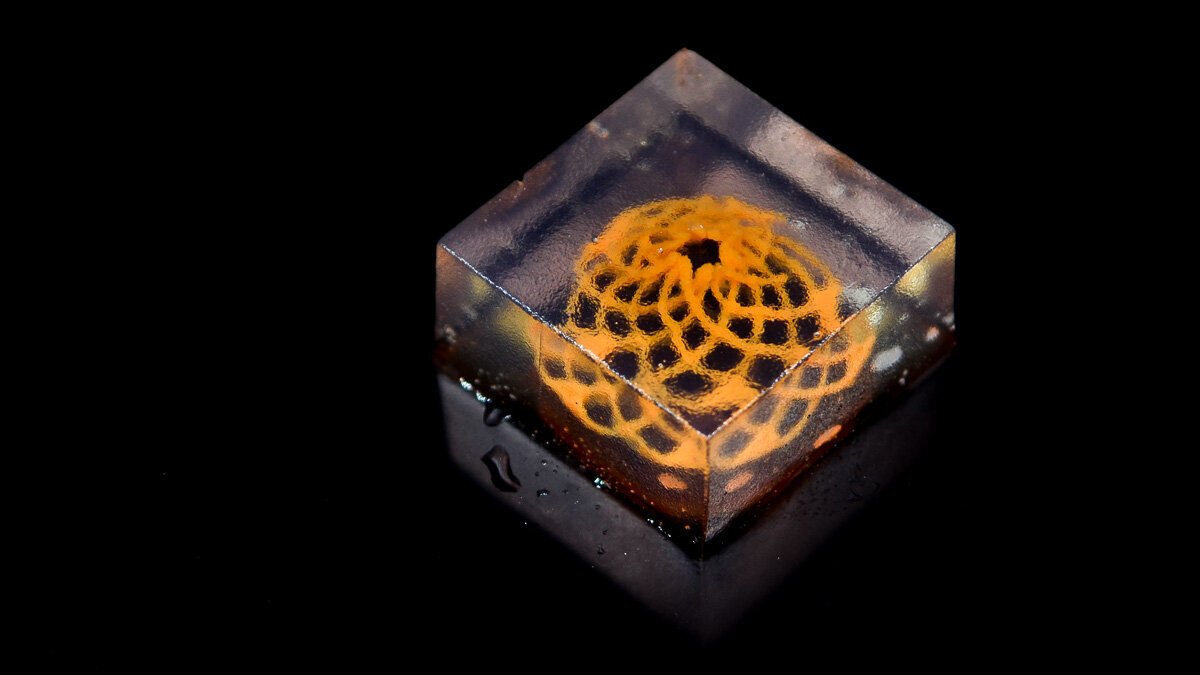

From providing nutrition to being social platforms, food plays an essential role in our daily lives and cultures. In HCI, we are interested in using food as an interaction medium and a context of personal fabrication. We seek to expand the design space of 3D printed food by adapting support bath-assisted printing to the food context.

This technique, namely embedded printing, by which freeform soft materials are extruded inside a goop-like medium for bio-engineering and regenerative medicine, has been adopted in additive manufacturing such as Rapid Liquid Printing.

The goop-like medium is made of fine bits of gel. Just like a pool of sand or a ball pit, this medium allows any object, even it is readily liquidy, to float inside while maintain its shape.

The medium, or so-called support bath, is usually bio-compatible, bio-safe, water-based, and edible.

Edible - this provides us the perfect platform to make food-based 3D prints.

This technique, namely embedded printing, by which freeform soft materials are extruded inside a goop-like medium for bio-engineering and regenerative medicine, has been adopted in additive manufacturing such as Rapid Liquid Printing.

The goop-like medium is made of fine bits of gel. Just like a pool of sand or a ball pit, this medium allows any object, even it is readily liquidy, to float inside while maintain its shape.

The medium, or so-called support bath, is usually bio-compatible, bio-safe, water-based, and edible.

Edible - this provides us the perfect platform to make food-based 3D prints.

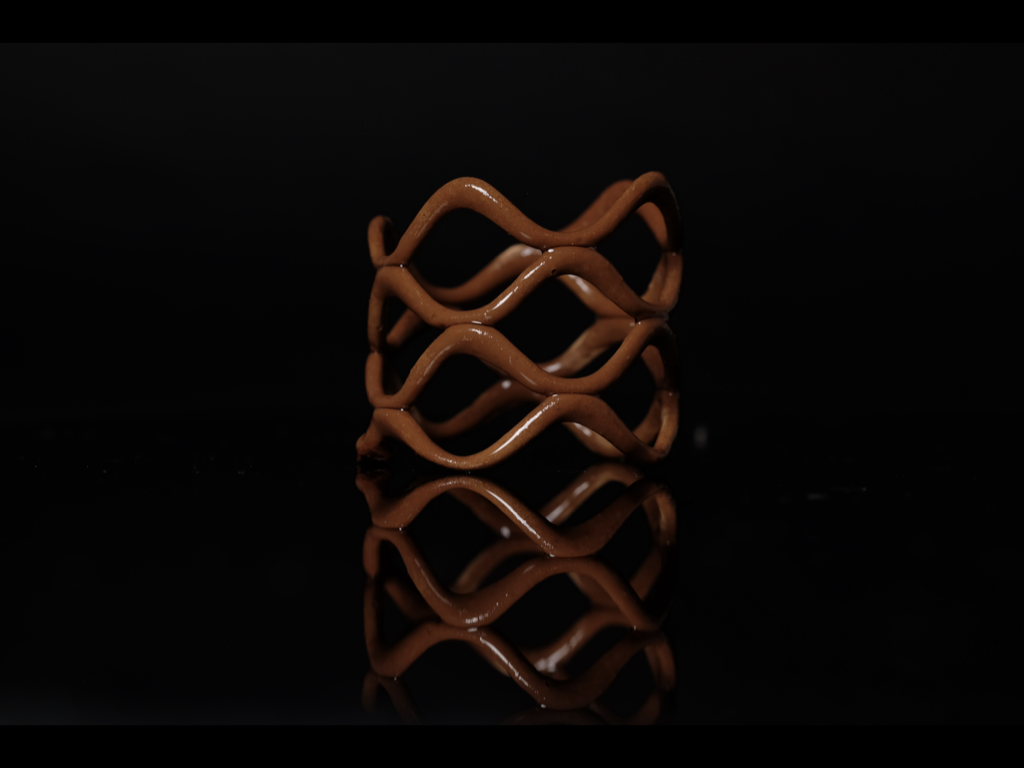

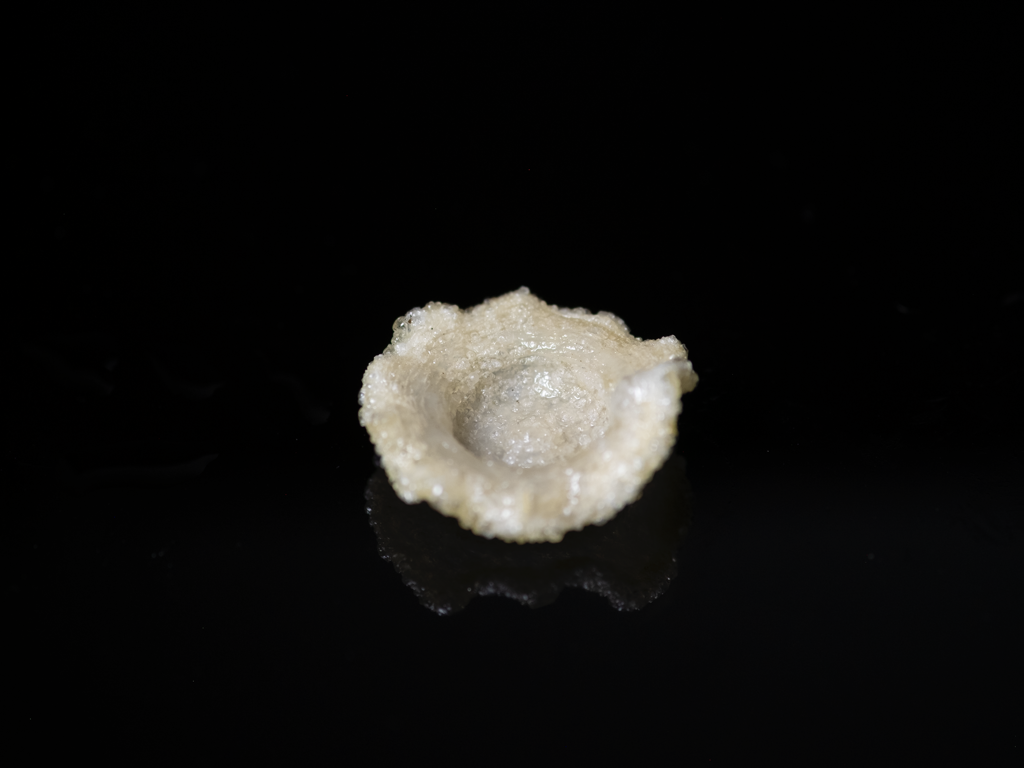

Chocolate is one of the popular ingredient used in food printing because of its readily viscous nature. There are recipes we can just copy and follow. But we are going for more impressive freeform designs.

It was a lot of trouble at first. We couldn’t get the chocolate out of the medium without breaking its intricate structure. The chocolate bar, after melted and printed, became gooey. As a chocolate pilgrim, I found this texture no where near off-the-shelf quality chocolate bars. Was something wrong with leaving the chocolate in a water medium? Was it the temperature? Was it… amorphous?

Then it hit me - let me check the phase diagram of chocolate. A phase diagram is what a materials scientist learns on day 1 of their training but ignores 99% of the time in their research or career, if they never have to work with metallurgy. This is one of the precious 1% moment - chocolate has a crystalline phase, which yields its lustre and mouthfeel in chocolate making among chocolate industry and chocolate dessert enthusiasts. If we print outside of this phase, it will never crystalize and shine.

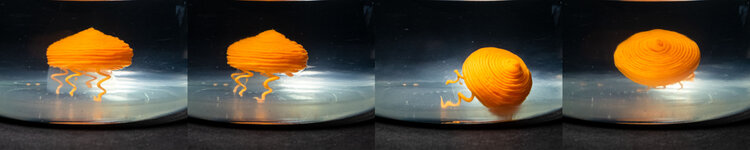

Then we just became very creative of what we are capable of printing - true freeform 3D shapes finished within a few minutes.

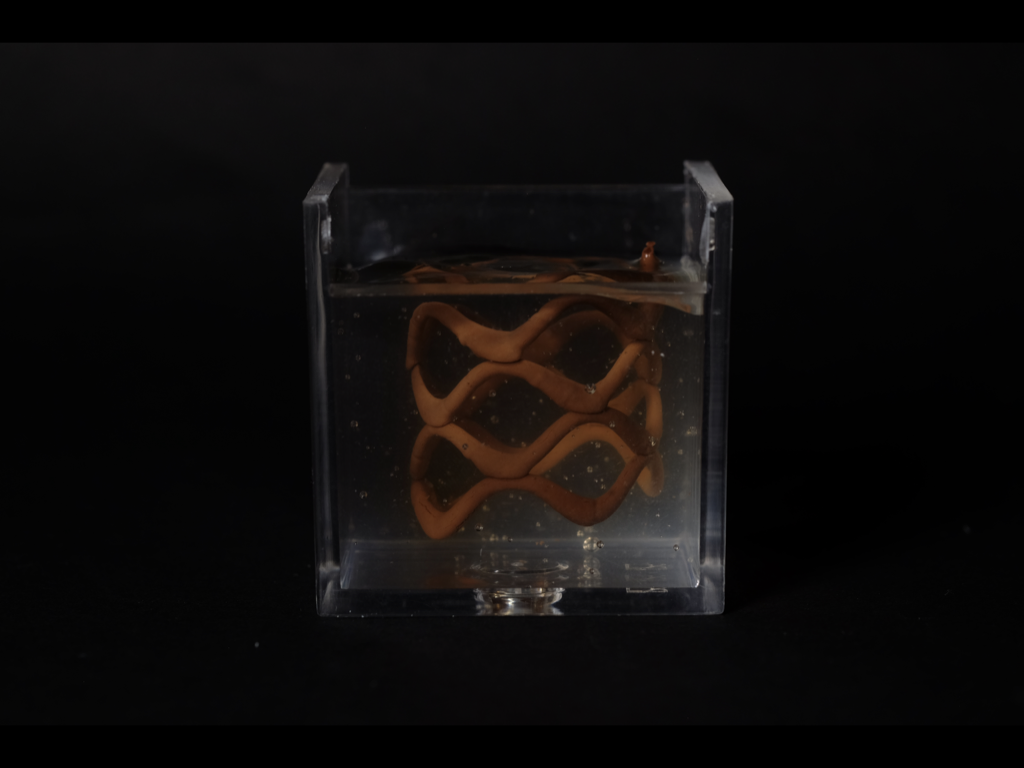

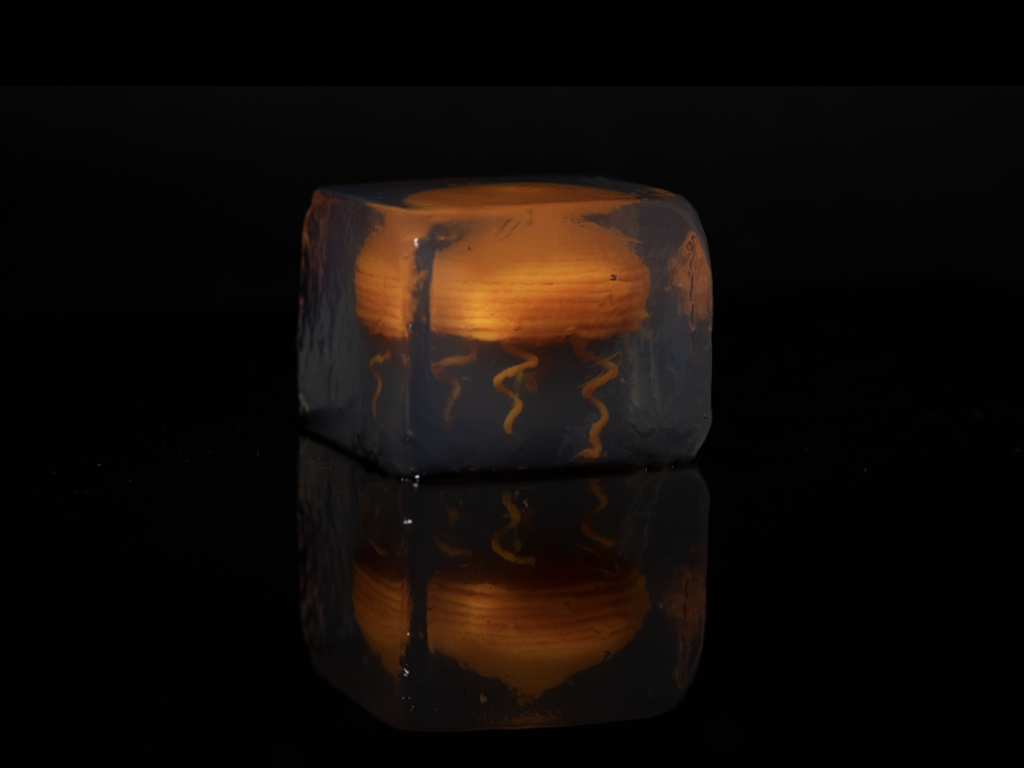

We care about the context. The jelly fish we printed is an example of liquid food in solid form (the gelatin block, melted in hot water) and interactive dining experience (the jelly fish, made of alginate, floats around inside of the hot soup).

It was a lot of trouble at first. We couldn’t get the chocolate out of the medium without breaking its intricate structure. The chocolate bar, after melted and printed, became gooey. As a chocolate pilgrim, I found this texture no where near off-the-shelf quality chocolate bars. Was something wrong with leaving the chocolate in a water medium? Was it the temperature? Was it… amorphous?

Then it hit me - let me check the phase diagram of chocolate. A phase diagram is what a materials scientist learns on day 1 of their training but ignores 99% of the time in their research or career, if they never have to work with metallurgy. This is one of the precious 1% moment - chocolate has a crystalline phase, which yields its lustre and mouthfeel in chocolate making among chocolate industry and chocolate dessert enthusiasts. If we print outside of this phase, it will never crystalize and shine.

Then we just became very creative of what we are capable of printing - true freeform 3D shapes finished within a few minutes.

We care about the context. The jelly fish we printed is an example of liquid food in solid form (the gelatin block, melted in hot water) and interactive dining experience (the jelly fish, made of alginate, floats around inside of the hot soup).