Contribution

concept designmaterials design

fabrication

basic electronics

written/visual documentation

Collaborator

Jianzhe GuFang Qin

Aditi Maheshwari

Andreea Danielescu

Jiaji Li

Yue Yang

Ye Tao

Lingyun Sun

Dinesh K. Patel

Supervisors

Lining YaoGuanyun Wang

Shu Yang

Teng Zhang

News Coverage

Science Friday | Nature News | NewScientist | Reuters | Plantae| CMU News | Penn Today | Seed World | FuturityConducted at Morphing Matter Lab, HCII, CMU

︎Nature article

︎UIST '20 Full paper

Aerial seeding is a crucial way to cover large and otherwise inaccessible areas, and can facilitate post-fire reforestation or wildland restoration. However, when a seed lies on the surface, it can be damaged by weather conditions or eaten by wildlife, resulting in low germination rates.

Inspired by erodium seed, which has evolved over million of years to absorb energy from its environment and drill itself into the ground for seeding purposes, E-seed is developed to tunnel through the ground. The seed carrier has a higher implantation success rate than that of Erodium seeds. This technology may improve the effectiveness of aerial seeding to address agricultural and environmental stresses in degraded regions.

E-seed not only represents our effort to reverse-engineer natural actuators, but also makes me ponder the relationship between human and nature, nature and materials science, materials science and design.

We do not just learn from nature. We are paying the knowledge forward to construct a synergetic environment.

Inspired by erodium seed, which has evolved over million of years to absorb energy from its environment and drill itself into the ground for seeding purposes, E-seed is developed to tunnel through the ground. The seed carrier has a higher implantation success rate than that of Erodium seeds. This technology may improve the effectiveness of aerial seeding to address agricultural and environmental stresses in degraded regions.

E-seed not only represents our effort to reverse-engineer natural actuators, but also makes me ponder the relationship between human and nature, nature and materials science, materials science and design.

We do not just learn from nature. We are paying the knowledge forward to construct a synergetic environment.

Our latest submission was accepted at Nature as the cover story.

We sourced our inspiration from the plant Erodium.

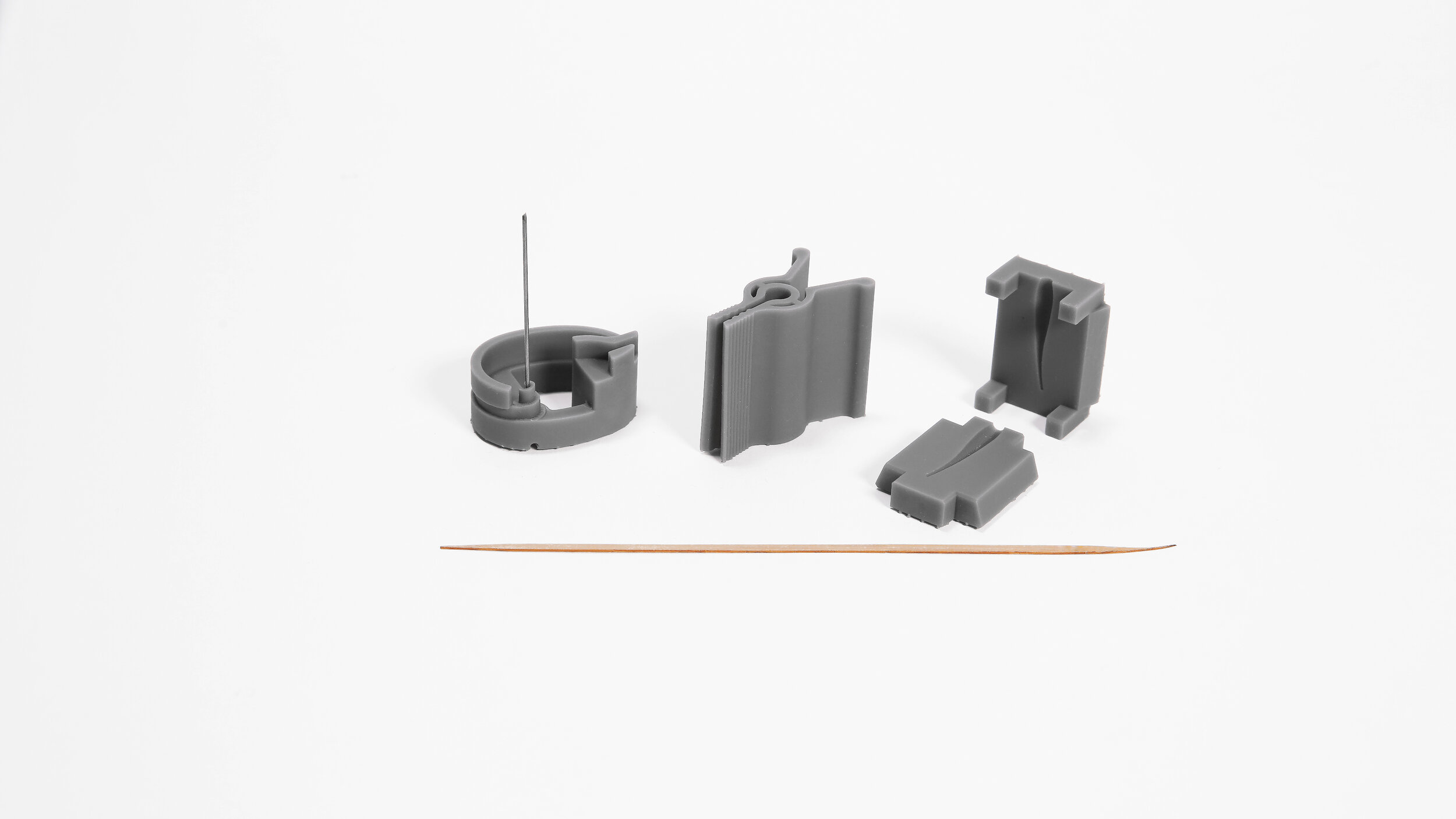

To reverse-engineer it, we first need to understand it. We built a spray chamber to mimic raining, bought a hundreds of different varieties of Erodium seeds, and observe how they behave.

To reverse-engineer it, we first need to understand it. We built a spray chamber to mimic raining, bought a hundreds of different varieties of Erodium seeds, and observe how they behave.

There is the bit of materials science in the project. We searched and tested a variety of materials and processing techniques. It came down to a wood composition eventually, because it is about right - chemically identical to Erodium seed as they are both plant-based, degradable, shapeable, and water-responsive.

We processed the wood in-house. Lumbers were chopped down to blocks, run through multiple wood-preping steps to get smooth, thin, controlled veneers we wanted. The image shows me operating a jointer to prep wood surface.

I always love a project when I learn new techniques of crafting.

We processed the wood in-house. Lumbers were chopped down to blocks, run through multiple wood-preping steps to get smooth, thin, controlled veneers we wanted. The image shows me operating a jointer to prep wood surface.

I always love a project when I learn new techniques of crafting.

A resemblance in look and function, utilizing the materials engineering knowledge to transfer a piece of wood veneer into a humidity-responsive coiling actuator.

And of course it can drill.

This work was done when the States were in lockdown. Our lab prepared a documentary of WFH situation that you can view here. The clip below is my part, recorded by myself, to reveal the actual working conditions while I developed E-seed near the submission. It has lasted until today, but hopefully I will update when it ends.